Back to top

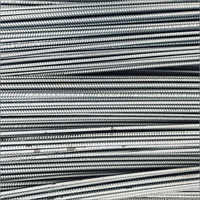

An experienced manufacturer of TMT Iron Bar, 8 MM TMT Bar, Industrial TMT Bar, TMT Bar, etc..

About Us

Sachdeva Steel Products has been a leading manufacturer and supplier of high-grade TMT bars since 1984. Our collection includes Industrial TMT Bars, 12 MM TMT Bars, Construction TMT Bars, 25 MM TMT Bars, etc. With the support of a dedicated team of professionals and cutting-edge manufacturing procedures, we have been able to achieve this prestigious position for our products in the national market. Over the course of more than 30 years, our company has established a strong presence by addressing all of our customers product expectations. We have become one of the most eminent organizations that create and distribute TMT bars by hiring skilled people and continually upgrading our steel re-rolling facilities. We have an amazing monthly manufacturing capacity of 3000 MT bars, which allows us to produce products and meet urgent or large-scale requests within the specified time frame.

Our Associate Companies

Values

In our active years of production, the most valuable thing we have won is our customers trust, which we have gained by providing them with the highest quality bars such as 12 MM TMT Bars, Industrial TMT Bars, 25 MM TMT Bars, Construction TMT Bars, etc. Client trust is our most prized asset, and we work tirelessly to maintain it through ethical business methods. We have constantly invested in continuing technological advancements, strengthening technical abilities, and maintaining a robust quality system in order to better serve our clients.

Strong Team Spirit

The employees hired in our company work in a coordinated manner so that they can share knowledge and information in order to achieve the company goals. We are confident in our ability to realize our aim of being a world-class steel bar manufacturer since we have a team of well-educated and motivated professionals.

Customer-Orientation

Our top focus is to maintain our commitment to providing our clients with the best products possible like Construction TMT Bars, 12 MM TMT Bars, 25 MM TMT Bars, Industrial TMT Bars, etc. We appreciate all comments from our consumers so that we can improve our product to meet their needs.

Expertise

Our expertise is based on our staff extensive knowledge and professional skills, which they use to implement new technologies and processes in order to provide our clients with excellent bars. For our innovative technology, we always hire personnel with adroit knowledge and competent skills. We maintain the advancement of our manufacturing techniques by undertaking ongoing research to learn new methods of production and increase the overall efficiency of our business operations.

Vision

Our company is entering the market with the goal of achieving a notable position in the bars sector by providing the highest quality items to clients at reasonable prices. We hope that by doing so, we will assist the construction sector in building robust, earthquake-resistant structures. By providing such high-quality items to our clients, we hope to motivate our entire organization to contribute to the nation's growth.

Serving Top Quality

We are advancing in the industry with the goal of achieving maximum customer satisfaction, technical breakthroughs in the production setup, and cost-effectiveness of the range. We are committed to providing our customers with better goods that are durable and able to resist a variety of industrial circumstances. The following procedures are followed in the production of our TMT bars to achieve the requisite perfection:

Before and after controlled water quenching, we undertake Hot Quenching treatment on the bars to ensure their strength. Sachdeva Steel Products is pleased to hold ISO 9001 certification for itself, as well as ISI accreditation for our TMT Bars.

More About Us

The Sachdeva Group began operations in 1984 with the opening of a steel re-rolling plant with a monthly production capacity of 1200 MT. Our organization has made great progress as a result of technological improvements and the tireless work of our professionals. This company has now erected an in-house sophisticated steel re-rolling plant and engaged more than 500 dedicated employees to manage its operations, resulting in a massive increase in bar production capacity to 3000 MT. This companys main offering to the steel market is a line of high-grade steel TMT (Thermo Mechanical Treated) Bar.

Sachdeva Steel Products has been a leading manufacturer and supplier of high-grade TMT bars since 1984. Our collection includes Industrial TMT Bars, 12 MM TMT Bars, Construction TMT Bars, 25 MM TMT Bars, etc. With the support of a dedicated team of professionals and cutting-edge manufacturing procedures, we have been able to achieve this prestigious position for our products in the national market. Over the course of more than 30 years, our company has established a strong presence by addressing all of our customers product expectations. We have become one of the most eminent organizations that create and distribute TMT bars by hiring skilled people and continually upgrading our steel re-rolling facilities. We have an amazing monthly manufacturing capacity of 3000 MT bars, which allows us to produce products and meet urgent or large-scale requests within the specified time frame.

Our Associate Companies

- M/s. Jai Jagdish Ship Breaking Pvt Ltd.: It was founded in the year 1998. This unit is also responsible for ship breaking. Until now, this unit has demolished 31 ships.

- M/s. Sachdeva Steel Product Ship Breakers: This venture was founded in 1995 and is associated with ship-breaking activity. Until now, this unit has demolished 31 ships

- M/s. Sachdeva Industries Ltd (Steel Division): Sachdeva Group started this Induction Furnace plant in 2008. It has a production capacity of 25000 M.T. of steel ingots per year. This device produces 3 1/4 X 4 1/4 inch ingots.

- M/s. Sachdeva Oxygen Industries: It was in the year in the year 1995 was formed under the name of Sachdeva Industries Ltd. Has an outstanding production capacity of 175 cubic meters/hour.

Values

In our active years of production, the most valuable thing we have won is our customers trust, which we have gained by providing them with the highest quality bars such as 12 MM TMT Bars, Industrial TMT Bars, 25 MM TMT Bars, Construction TMT Bars, etc. Client trust is our most prized asset, and we work tirelessly to maintain it through ethical business methods. We have constantly invested in continuing technological advancements, strengthening technical abilities, and maintaining a robust quality system in order to better serve our clients.

Strong Team Spirit

The employees hired in our company work in a coordinated manner so that they can share knowledge and information in order to achieve the company goals. We are confident in our ability to realize our aim of being a world-class steel bar manufacturer since we have a team of well-educated and motivated professionals.

Customer-Orientation

Our top focus is to maintain our commitment to providing our clients with the best products possible like Construction TMT Bars, 12 MM TMT Bars, 25 MM TMT Bars, Industrial TMT Bars, etc. We appreciate all comments from our consumers so that we can improve our product to meet their needs.

Expertise

Our expertise is based on our staff extensive knowledge and professional skills, which they use to implement new technologies and processes in order to provide our clients with excellent bars. For our innovative technology, we always hire personnel with adroit knowledge and competent skills. We maintain the advancement of our manufacturing techniques by undertaking ongoing research to learn new methods of production and increase the overall efficiency of our business operations.

Vision

Our company is entering the market with the goal of achieving a notable position in the bars sector by providing the highest quality items to clients at reasonable prices. We hope that by doing so, we will assist the construction sector in building robust, earthquake-resistant structures. By providing such high-quality items to our clients, we hope to motivate our entire organization to contribute to the nation's growth.

Serving Top Quality

We are advancing in the industry with the goal of achieving maximum customer satisfaction, technical breakthroughs in the production setup, and cost-effectiveness of the range. We are committed to providing our customers with better goods that are durable and able to resist a variety of industrial circumstances. The following procedures are followed in the production of our TMT bars to achieve the requisite perfection:

- Raw billets procurement

- Physical and chemical testing

- Heating

- Hot rolling into TMT bars

- Controlled water quenching

- Physical testing

- Setting the batches for Dispatch

Before and after controlled water quenching, we undertake Hot Quenching treatment on the bars to ensure their strength. Sachdeva Steel Products is pleased to hold ISO 9001 certification for itself, as well as ISI accreditation for our TMT Bars.

More About Us

The Sachdeva Group began operations in 1984 with the opening of a steel re-rolling plant with a monthly production capacity of 1200 MT. Our organization has made great progress as a result of technological improvements and the tireless work of our professionals. This company has now erected an in-house sophisticated steel re-rolling plant and engaged more than 500 dedicated employees to manage its operations, resulting in a massive increase in bar production capacity to 3000 MT. This companys main offering to the steel market is a line of high-grade steel TMT (Thermo Mechanical Treated) Bar.

Most Popular Product

SACHDEVA STEEL PRODUCTS

Bhavnagar, Gujarat

Bhavnagar, Gujarat

508/GIDC, Phase-2, Sihor, BNo 0, Opp Swaminaryan Mandir, Lokhand Bazar, Bhavnagar - 364001, Gujarat, India

Phone :08045813445

|

|

SACHDEVA STEEL PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |